vickers hardness test specimen|vickers hardness test explained : vendor The general principle of the Vickers and Knoop indentation hardness test consists of two steps: Step 1 - The applicable specified indenter is brought into contact with the test specimen in a . webEra dia 6 de dezembro de 2023 quando o Palmeiras confirmou o título brasileiro, tornou-se dodecacampeão nacional e assim promoveu uma mudança no cenário do futebol da .

{plog:ftitle_list}

23 de fev. de 2024 · O Corpo de Bombeiros foi acionado para conter o fogo. Um dos assaltantes, de 28 anos, estava no local e foi preso. Posteriormente, foi verificado que .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

When doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work-hardened regions and effects of the edge. These minimum distances are different for ISO 6507-1 and ASTM E384 standards. Vickers values are generally independent of the test force: they will come out the same for 500 .The general principle of the Vickers and Knoop indentation hardness test consists of two steps: Step 1 - The applicable specified indenter is brought into contact with the test specimen in a .

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our . Unlike the Rockwell method, where the application is quite minimal, the Vickers method can be used for ll types of test materials and specimens. Due to its scaling, the Vickers hardness test is ideal for testing .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three .

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F [N]), the .The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and the .

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the .

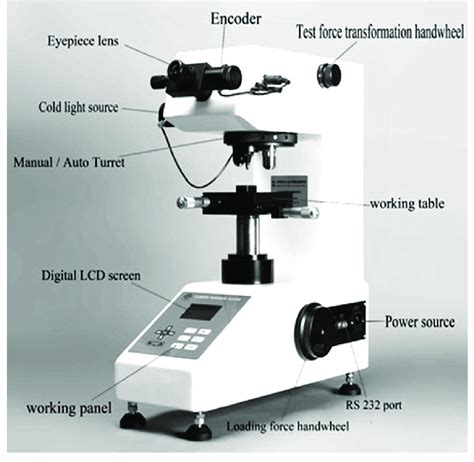

vickers hardness testing machine diagram

vickers hardness test procedure pdf

water bottle brand ph test

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard .The Vickers test often has strict specimen requirements due to the high sensitivity of the optical reading instrument and the need to get an accurate result. This article provides what you need to know for adequate preparation of your specimen for an accurate Vickers hardness test. + 86 755 61301520; [email protected]; Search. Home; About .Hardness tests measure the resistance of a material against plastic deformation.To perform these tests (be it Brinell, Rockwell, or Vickers), an indenter is pressed on the surface of the specimen with a specific force F F F for a time interval of, say, 10-15 s.During this interval, the material undergoes plastic deformation, which you will measure after unloading the material specimen.

The Vickers hardness test works on the same procedure, as any other hardness test. The test force is applied on an indenter to create a penetration on the test specimen. For this surface of the test needs to be straight and polished. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method. The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.

Verification - checking or testing to assure conformance with the specification. Vickers testing machines shall be verified periodically using test blocks. Vickers hardness machine - The testing machine shall support the test specimen and control the movement of the indenter into the specimen under a preselected test force,The Vickers hardness test was developed in 1921 by . Hardness testing specimen. 5. Standard hardness test block. ( for B& C scales). Material Testing Lab 18MEL37A/47 A Mechanical Dept., Atria Institute of Technology, Bengaluru Page 12 Procedure: 1. Place the semi polished specimen on the platform.

Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly.

The advantages of the Vickers hardness test are that extremely accurate readings can be taken, and just one type of indenter is used for all types of metals and surface treatments. . 3.1.4 Place the standard block or the specimen on the testing table and then rotate the hand wheel to raise the table. WhenSee 5.10 for the proper reporting of the hardness level from measurements of area or depth of the indentation made by and scale. forcing a specified indenter into the surface of a material under as-found condition, n— specified static loading conditions. 3.2.5 the state of the hardness ma- chine as reflected by the initial verification .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. . Depending on the test force and the specimen material used, Vickers hardness values typically range between 1 and 3,000 HV. Application of Test Force:Download scientific diagram | Vickers hardness test specimen. from publication: Genetic algorithm based optimization of friction welding process parameters on AA7075-SiC composite | Friction . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

Vickers and Knoop hardness test methods are defined in the following standards: ASTM E384 and ISO 6507. It is recommended that operators have a current copy . or simply to determine the hardness of specimens too small for traditional bulk indentation tests. For additional information on Vickers hardness testing and metallographic hardness .

The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. . Specimen Size The Vickers hardness test method is based on the least area by which the indentation is required to be made. The specimen’s size .Specimens randomly selected and submitted to a Vickers hardness test with a diamond pyramid head of a Duramin-1 Vickers hardness tester (Struers) under a predetermined load (9.807 N) over 15 s to induce a diamond-shaped indent. The size of each diagonal distance was measured and the Vickers hardness was calculated according to the surface area .

The Wilson® VH1150 Vickers Series Hardness Testers offer a versatile and user friendly solution for a wide range of hardness scale testing. For single scale hardness testing, the Wilson VH1150 Tester is equipped with a five-position turret which includes one indent- . testing templates (“specimen”) to speed up your operation. DiaMet is .A standard Vickers Hardness test was conducted on a metal specimen. Determine the Vicker’s hardness number and the tensile stress of the specimen. The applied load was 10 kgf, and the standard indentor left an indentation with diagonal d = 0.217 mm. Assume that the metal is hard.

The Vickers hardness test operates on similar principles to the Brinell test, the major difference being the use of a square based pyramidal diamond indentor rather than a hardened steel ball. . Similarly, if the impression is too close to the specimen edge then low hardness values will be recorded - again as a rule the impression should be .

In the early days of low-load (<100 gf) hardness testing, it was quickly recognized that improper specimen preparation can influence hardness test results. Most texts state that improper preparation yields higher test results because the surface contains excessive preparation-induced deformation. . Fig. 5 - Load vs. Vickers hardness test .With Vickers, Knoop and Brinell, your test tasks are carried out in a load range between 0.25 g and 62.5 kg Depending on the hardness of the specimen to be tested and the selected method, different lenses enlarge your test indentation.. Your hardness measurements are displayed on your screen in high resolution.The specimen size (the minimum clearances between test points (indent spacing) and from the specimen edge (edge clearance) for Vickers defined in the standard must be observed); The specimen thickness (the specimen thickness must be at least 1.5 times the indentation diagonals, i.e. the minimum specimen thickness must be between 0.085 and 6.5 mm); The .

Hence, this work aims to study the mechanical behaviour of a specimen of tungsten carbide cobalt (WC-Co) during a Vickers indentation test, based on FE calculations with the commercial solver MSC .

water bottle brands test

vickers hardness test procedure

We continue our journey with our four stylish & ambitious best girlfriends in Harlem NYC as they explore new levels of love and loss, career highs and lows, and their friendship .

vickers hardness test specimen|vickers hardness test explained